How To Build a Strategic Fleet Maintenance Plan + Checklist

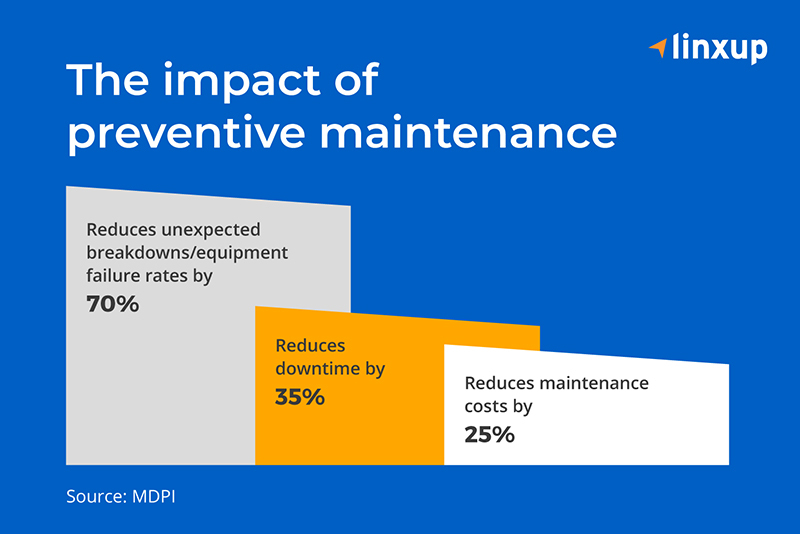

For small to mid-sized field service-based businesses, reliable vehicles are everything. A solid fleet maintenance plan keeps your vehicles running at their best and, more importantly, keeps your business moving. With a preventative maintenance plan, you can avoid surprise breakdowns, reduce downtime, and minimize repair costs so you can fit more jobs in each day.

To help you build a proactive fleet maintenance plan, or revamp the one you currently have in place, we’ve detailed where to start and how to create a checklist that keeps your teams accountable.

For field service businesses, reliable vehicles mean more jobs and fewer headaches. A good maintenance plan helps you prevent breakdowns, cut repair costs, and reduce downtime.

Whether you're starting from scratch or improving your current setup, we’ll show you how to build a proactive plan—and create a checklist your team can stick to.

Understanding fleet maintenance plans

When it comes to the upkeep of company vehicles, a well-structured fleet maintenance plan holds the key to reliability, safety, and cost-effectiveness.

With this valuable tool in your belt, you can avoid expensive breakdowns, extend vehicle lifespan, and maintain a safe and compliant fleet.

Benefits of a fleet maintenance plan

There are plenty of benefits of fleet maintenance, including:

- Reduced downtime: Regular maintenance prevents unexpected breakdowns, keeping your vehicles on the road and your operations running smoothly.

- Longer vehicle lifespan: A well-maintained fleet lasts longer, saving you from early or unexpected part replacements and helping you get your money’s worth out of every truck. Studies show that predictive maintenance can lengthen vehicle lifespan by 20%.

- Improved fuel efficiency: When vehicles are properly maintained, you save money on fuel and tires. Regular tire rotations, alignments, and pressure checks help you get more MPG and stretch your tire life.

- Better resale value: Well-maintained vehicles hold their value longer — which means you get even more for your investment when it’s time to sell or upgrade your fleet.

- Stay in compliance: Regular maintenance ensures your fleet meets all safety and regulatory requirements.

- Better planning: A maintenance plan allows you to schedule maintenance tasks in advance, limiting disruptions to your daily operations and allowing for better resource allocation and planning.

Improved fleet safety: Regular inspections and maintenance keep your vehicles safe for your drivers and everyone sharing the road with them.

Preventive maintenance vs. reactive maintenance

Preventive maintenance involves regularly scheduled services (think oil changes, brake inspections, and tire rotations) that are performed to prevent problems before they pop up.

Reactive maintenance, on the other hand, only addresses issues after they happen, often leading to bigger repairs, emergencies, and unexpected downtime.

Preventive maintenance is generally more cost-effective in the long run, as it minimizes breakdowns and extends vehicle lifespan. Some fleets also conduct predictive maintenance, which involves monitoring the real-time condition of vehicles and carrying out maintenance tasks as necessary.

Key elements of a fleet preventive maintenance plan

A thorough fleet preventive maintenance plan includes several key building blocks:

Asset inventory

Start by creating a detailed inventory of all fleet vehicles and equipment. Include make, model, year, VIN, license plate number, and current mileage or hours of operation.

This inventory serves as the foundation for tracking maintenance schedules and history. Tools like Linxup’s Vehicle Maintenance Tracker and Scheduling Program can help you centralize and manage this information.

Maintenance schedule

To keep your fleet in top condition, set up a maintenance schedule based on time intervals, mileage, or usage hours. For example:

- Oil changes: Every 5,000 miles or six months

- Tire rotations: Every 5,000 miles

- Equipment servicing: After every 200 operating hours

Customize the schedule to each vehicle's specifications and usage patterns.

Inspection protocols

Implement routine inspections to identify issues early, preventing costly repairs and downtime. Use standardized checklists for daily, weekly, and monthly inspections for consistency, thoroughness, and transparency. Take time to train all drivers and maintenance personnel to perform these inspections properly.

Service documentation

It's important to keep detailed records of all maintenance activity for compliance and tracking purposes.

Your maintenance records should include dates, services performed, meter readings, parts used, people involved, and costs. Accurate documentation is also helpful for forecasting future maintenance needs.

Responsibility assignment

Clearly define the roles and responsibilities in the maintenance plan. This includes designating who is responsible for daily checks, what tasks are done by in-house mechanics vs. outsourced service providers, and fleet manager oversight. For the plan to be successful, everyone should be aligned with clear communication and accountability.

Budgeting

A detailed maintenance budget should cover more than just the basics, like oil changes and tire rotations. Set aside funds for routine upkeep, but also leave room for the unexpected, so one major repair doesn’t derail your business.

Monitor expenses to identify trends and opportunities for cost savings. For example, is tire wear occurring more frequently on a particular vehicle? It might be due to alignment issues that, if fixed early, can reduce future costs. Keeping an eye on these patterns helps you make informed decisions and maintain a healthy budget.

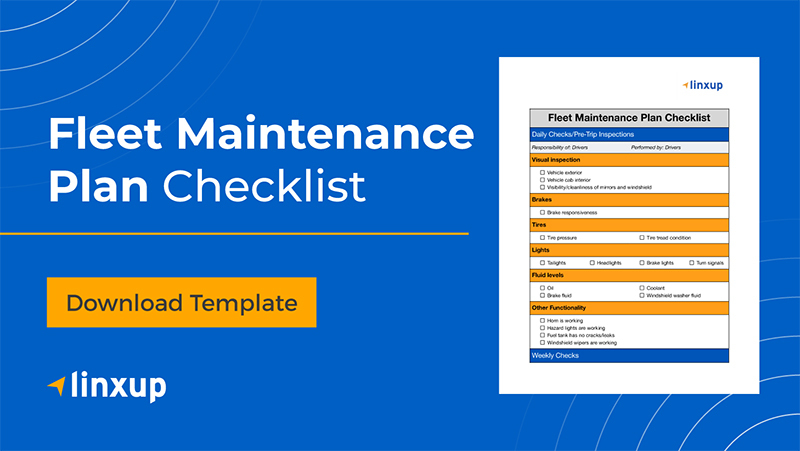

Fleet vehicle maintenance checklist

A fleet maintenance plan checklist keeps you and your team on track. When maintenance becomes part of the regular routine, it helps you avoid breakdowns and extended downtimes. You can customize your fleet maintenance plan to align with your specific operational needs, making it easier to stay organized and prioritize what’s important to your business.

Here's a sample checklist to give you an idea of what your fleet maintenance plan template could include:

Download our comprehensive Fleet Maintenance Plan PDF Checklist here.

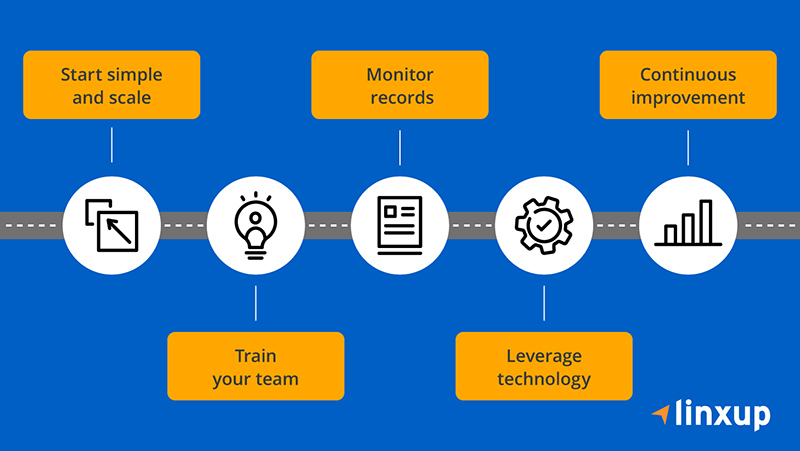

How to implement a fleet maintenance plan

Implementing a fleet maintenance plan requires careful planning and execution. Here are our recommendations to set you up for success:

Start simple and scale

Begin with a basic maintenance plan focusing on essential tasks. As you gather data and experience, you can refine and expand the plan to include more detailed procedures and schedules. This allows you to adapt the plan to your specific needs and avoid overwhelming your team with too much change at once.

Train

Educate your team on the importance of maintenance, how to perform their assigned tasks, and timeframe expectations. Provide training sessions for drivers and encourage prompt reporting of issues.

Monitor

Make it part of your routine to review maintenance records. This gives you a chance to identify patterns and catch recurring issues. Use this information to make informed decisions and improve the maintenance plan. Maintain clear communication with drivers, mechanics, and service providers every step of the way.

Leverage technology

Fleet management software like Linxup helps automate maintenance scheduling, track service history, set reminders, and provide valuable insights into your fleet’s performance. This can significantly improve your maintenance processes and increase efficiency.

Update and improve

Regularly review and update your maintenance plan based on feedback, new business needs, performance data, and manufacturer recommendations.

Ask for feedback from staff and stay informed about industry best practices to aim for ongoing improvement.

Invest in your fleet’s future with Linxup

Consistent care matters. A well-defined fleet maintenance plan is a smart investment in the longevity, safety, and efficiency of your business. By proactively managing your fleet’s maintenance, you can minimize disruptions, cut costs, and ensure the safety of your drivers.

Ready to take the next step in optimizing your fleet’s performance? Linxup offers comprehensive fleet management solutions, including a vehicle maintenance tracker designed to streamline maintenance tracking and scheduling. Our platform provides real-time insights, automated reminders, and detailed reporting to help you maintain a reliable and efficient fleet.

Contact our team today to learn how Linxup can support your fleet management needs. With over 20 years of fleet technology development, we’re ready to put our innovations to work for you and your vehicles.

Fleet maintenance plan FAQ

How often should I schedule fleet maintenance?

Maintenance frequency depends on vehicle type, time, mileage/usage, and manufacturer recommendations. Common intervals include oil changes every 5,000 miles, tire rotations every 5,000 miles, and thorough inspections quarterly or annually. Consult manufacturer recommendations and your own experience to determine the optimal intervals for your fleet.

Who is responsible for following the fleet maintenance plan?

Everyone involved in fleet operations plays a role. Responsibilities are typically divided among drivers for daily inspections, mechanics or service providers for scheduled maintenance, and fleet managers for overseeing the entire process. Clear role definitions encourage accountability and effective execution of the maintenance plan.

What’s the difference between preventive and corrective maintenance?

Corrective maintenance is reactive, addressing problems only after they arise. Preventive maintenance is proactive, aiming to prevent issues before they occur. It features regularly scheduled services for vehicles, which is generally more cost-effective and reduces downtime.

How can a fleet maintenance plan be customized for different types of vehicles?

Different vehicles have different maintenance needs. Customize maintenance schedules based on each vehicle’s make, model, usage patterns, and manufacturer guidelines. Also consider factors like operating conditions and load types as you tailor your plan.

How can technology help with fleet maintenance planning?

Taking advantage of technology can enhance efficiency and timely maintenance. For example, fleet management software like Linxup automates maintenance scheduling, tracks service history, sends reminders, and gives you insightful analytics to optimize your maintenance strategy.

For more information on how Linxup can help with your fleet maintenance planning, explore our fleet tracking solutions.