DOT Inspection Guide + Prep Checklist

| A DOT inspection is a required safety check that ensures commercial motor vehicles and drivers meet federal safety rules. It covers driver documents and key vehicle parts like brakes, tires, and lights. The goal is to keep unsafe trucks off the road and prevent accidents. |

If your trucks are on the road, DOT inspections are part of the job. Through July 2025, there have been over 1.75 million inspections, with about 1 million showing violations and 350,000 serious out-of-service (OOS) issues that can take trucks off the road. These inspections can be quick and easy — or they can cost you time, money, and customers.

Failing a DOT inspection also hurts your safety record and leads to bigger headaches down the line. But with the right prep, you can keep crews moving and avoid most inspection issues.

See what a DOT inspection looks like, how to prepare your trucks, and a quick checklist for the road.

What is a DOT inspection and how does it work?

A DOT inspection is a commercial vehicle inspection required by the Department of Transportation (DOT) to make sure both drivers and vehicles meet federal safety standards. The goal is to keep unsafe vehicles and drivers off the road.

The Federal Motor Carrier Safety Administration (FMCSA) oversees these truck inspections. FMCSA assigns certified state or federal inspectors to do them, often at weigh stations, roadside, or during scheduled checks at your yard.

Most commercial motor vehicles need an annual inspection, but you can also be stopped for roadside inspections at any time.

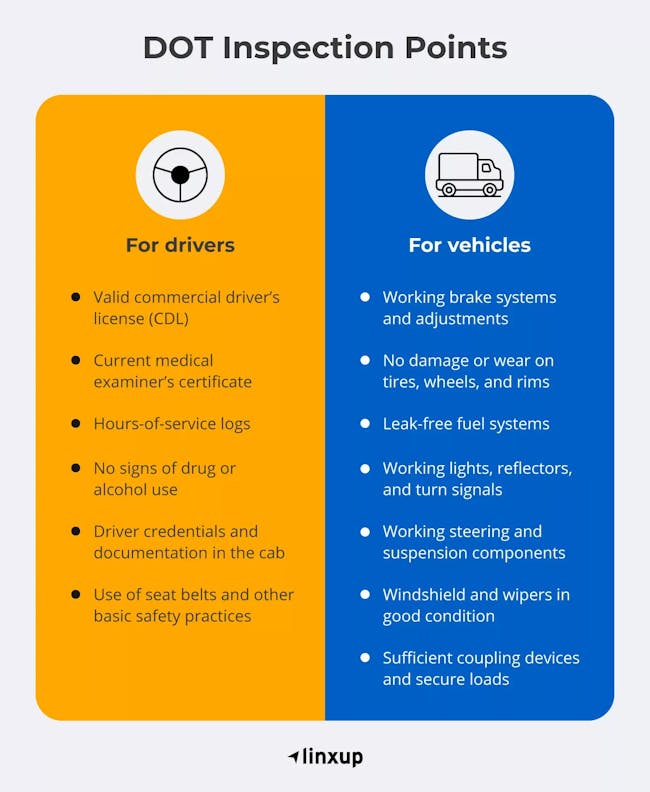

DOT driver inspection

Inspectors want to confirm you’re qualified and follow the rules by looking for:

- A valid commercial driver’s license (CDL)

- Up-to-date medical examiner’s certificate

- Hours-of-service logs that match regulations

- No signs of drug or alcohol use

- Correct driver credentials and documentation in the cab

- Use of seat belts and other basic safety practices

DOT vehicle inspection

To ensure the vehicle itself is road-ready and safe to operate, inspectors look at key systems and safety features, including:

- Brake systems and adjustments

- Tires, wheels, and rims for wear or damage

- Lights, reflectors, and turn signals

- Steering and suspension components

- Fuel systems for leaks

- Windshield wipers and windshield condition

- Coupling devices and securement of loads

DOT inspection levels

The FMCSA has eight inspection levels, each focusing on different aspects of the driver, vehicle, or both. Here’s what each DOT truck inspection level covers:

| Inspection level | What’s covered | Frequency |

| Level 1 | Full driver and vehicle check, including documents, safety equipment, and mechanical systems | Common during roadside blitzes or random stops |

| Level 2 | Driver documents plus visual inspection of key vehicle components (no under-vehicle check) | Common at weigh stations or roadside |

| Level 3 | Driver credentials, medical certificate, hours-of-service logs, and carrier info | Frequent during roadside stops |

| Level 4 | One-time check of a specific component or safety issue | Rare; tied to research or trend investigation |

| Level 5 | Complete vehicle inspection from Level 1 without a driver present | After accidents, repairs, or at carrier facilities |

| Level 6 | Level 1 inspection plus extra requirements for certain radioactive cargo | Required for qualifying shipments; rare otherwise |

| Level 7 | Local or state inspections, such as school buses, shuttles, or taxis | Varies by jurisdiction |

| Level 8 | Electronic verification of driver, vehicle, and carrier data | Anytime via wireless systems while in motion |

Level 1: North American standard inspection

Frequency: Most common during roadside blitz events or random stops; can happen any time of year

This is the most thorough inspection, covering both the driver and vehicle from top to bottom. Inspectors review all required documents and check the truck inside and out, including underneath. If the vehicle or driver fails any critical safety requirement, the truck may be placed out of service until the issue is fixed.

What’s inspected:

- Driver’s license and medical certificate

- Hours-of-service logs and seat belt use

- Alcohol or drug use indicators

- Brake systems and cargo securement

- Coupling devices, driveline/driveshaft, exhaust, and frame

- Fuel systems, lighting devices, and steering

- Tires, wheels, rims, hubs, and windshield wipers

- Emergency exits and electrical systems (for passenger vehicles)

Level 2: Walk-around driver/vehicle inspection

Frequency: Often done at weigh stations or roadside; takes less time than Level 1

This inspection is similar to Level 1, but inspectors don’t check under the vehicle. Instead, they do a visual walk-around, looking for obvious safety issues and checking driver credentials. It’s faster, but any serious defect can still take your truck off the road.

What’s inspected:

- All driver documents from Level 1

- Visual check of brakes, tires, lights, and cargo securement

- Coupling devices, exhaust systems, frames, and fuel systems

- Steering and suspension components

- Windshield wipers and overall exterior condition

Level 3: Driver/credential/administrative inspection

Frequency: Common during roadside stops and targeted safety checks

Level 3 focuses only on the driver, not the truck. Inspectors verify that all documents are current and in compliance, making sure the driver is legally qualified to operate the vehicle. If records are missing, expired, or inaccurate, fines or out-of-service orders can follow.

What’s inspected:

- Driver’s license and medical certificate

- Hours-of-service records and logbook accuracy

- Seat belt use

- Vehicle inspection reports

- Carrier identification and operating authority

Level 4: Special inspections

Frequency: Rare; conducted as part of research or targeted enforcement

Level 4 inspections are one-off checks that zero in on a single issue. They’re usually tied to research studies or to confirm a suspected safety problem. While rare, they can still lead to fines or repairs if the component doesn’t meet standards.

What’s inspected:

- A single component or safety system, such as brakes, tires, and lighting

- Items tied to a specific safety study or investigation

Level 5: Vehicle-only inspection

Frequency: Done without the driver present, often at a carrier’s facility, after an accident, or as part of a compliance review

This inspection checks every mechanical and safety system on the truck but skips the driver portion. Inspectors use the same process as a Level 1 for the vehicle itself. Level 5 inspection is common when a truck is being evaluated after repairs or following a crash investigation.

What’s inspected:

- All vehicle items from a Level 1 inspection

- No driver documentation or credentials

Level 6: North American standard inspection for transuranic waste and highway route controlled quantities (HRCQ) of radioactive material

Frequency: Required for all carriers moving HRCQ of radioactive material; rare in general trucking

This level is for specialized loads like certain radioactive materials. It adds extra safety and security checks on top of a standard Level 1 inspection. Unless your operation hauls this type of cargo, you’ll likely never see a Level 6 inspection.

What’s inspected:

- All Level 1 vehicle and driver items

- Additional radiological requirements and safety measures

- Compliance with handling and transport rules for HRCQ of radioactive material

Level 7: Jurisdictional-mandated commercial vehicle inspection

Frequency: Done under local or state programs; timing depends on jurisdiction rules

Some commercial vehicles operate only within a state or city and fall under local inspection rules. Level 7 covers those cases, from school buses to hotel shuttles. The inspection scope depends on the jurisdiction, and results aren’t part of federal DOT records.

What’s inspected:

- Vehicle components required under local or state inspection programs, such as school buses, taxis, and shuttles

- Requirements vary by jurisdiction

Level 8: North American standard electronic inspection

Frequency: Can happen at any time while a vehicle is in motion, through electronic or wireless data exchange

This is a contactless inspection done entirely through electronic systems without pulling the truck over. It verifies driver, vehicle, and carrier information in real time while the truck is on the road. This level is still evolving, but it’s designed to speed up compliance checks without slowing down freight.

What’s inspected:

- Driver credentials, medical certificate, and license endorsements

- Hours-of-service compliance

- Vehicle registration, operating authority, and insurance verification

- USDOT or Canadian NSC number

- Any active out-of-service orders

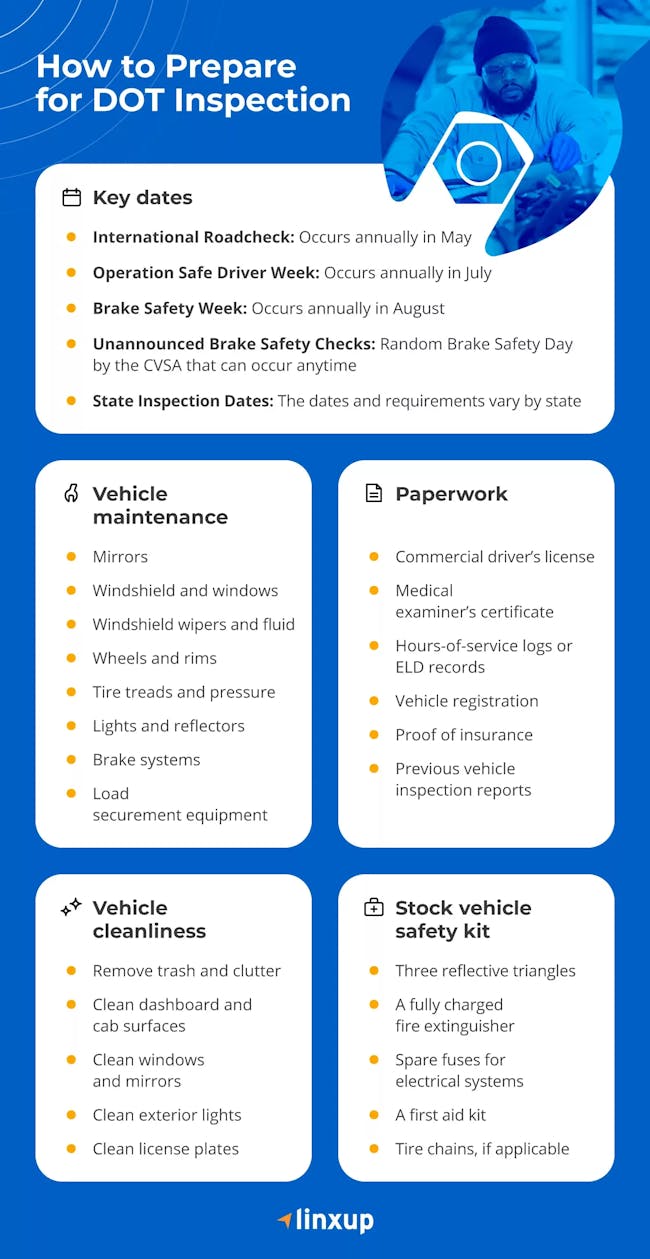

2025 and 2026 DOT inspection dates

Use the following DOT inspection dates for 2025 as reminders to put your fleet management tips into practice and keep your trucks, drivers, and records inspection-ready:

| Date | Event | What to expect |

| Annually in May | International Roadcheck | Level 1 road check, focusing on tire and Record of Duty status (RODS). |

| Anytime in 2025 | Random Brake Safety Day | Surprise one-day brake-focused enforcement by the CVSA with no prior warning |

| By December 31, 2025 | Annual DOT inspection deadline | Inspection stickers must be current to avoid fines or downtime |

| Dates vary by state | State inspections | Requirements vary by state |

Heads-up for 2026: Blitz dates for 2026 haven’t been announced yet. However, check the CVSA website regularly for the most current dates and inspection requirements. Also, annual DOT inspections follow a rolling 12-month cycle, so if your last inspection was June 15, 2025, your next is due by June 15, 2026.

7 most common DOT violations

DOT inspections are designed to catch real safety risks. Certain violations come up again and again, and knowing them helps you avoid fines, downtime, and hits to your safety score. Staying on top of these issues also reduces everyday fleet management challenges that slow operations.

Here are some of the most common issues inspectors flag:

- Brake system problems: Worn pads, out-of-adjustment brakes, or leaking air lines can put a truck out of service immediately

- Tire defects: Bald spots, tread depth below minimum, or visible damage like cuts and bulges

- Lights not working: Burned-out headlights, brake lights, turn signals, or missing reflectors reduce visibility and safety

- Hours-of-service violations: Logs that don’t match driving activity or exceed daily or weekly limits

- Faulty cargo securement: Straps, chains, or tie-downs missing, loose, or damaged, putting loads at risk of shifting

- Expired or missing driver credentials: Out-of-date CDL, medical certificate, or other required documentation

- Windshield and wiper issues: Cracked glass in the driver’s line of sight or wipers that can’t clear the windshield effectively

Tracking key fleet management KPIs like brake performance, tire condition, and driver hours can help you spot trouble before inspectors do.

DOT inspection checklist

A good fleet maintenance plan doesn’t just keep your trucks on the road; it also makes passing DOT inspections much easier. Use this checklist before trips and during routine upkeep to stay compliant and avoid downtime.

1. Address vehicle maintenance

Stay on top of mechanical issues before they turn into violations. Use fleet tracking systems to schedule and log regular maintenance, and do a walk-around before every trip.

What to check:

- Mirrors and glass for cracks or damage

- Wheels, rims, and lug nuts

- Tires for tread depth and proper inflation

- Lights, reflectors, and turn signals

- Brake systems and brake adjustments

- Load securement straps, chains, and tie-downs

- Windshield wipers and fluid levels

2. Gather and organize paperwork

An inspection can stall fast if you’re digging through a messy cab for documents. Keep everything in one easy-to-reach folder or binder so inspectors can review it quickly.

What to have handy:

- Commercial driver’s license

- Medical examiner’s certificate

- Hours-of-service logs or electronic logging device (ELD) records

- Vehicle registration

- Proof of insurance

- Previous vehicle inspection reports

3. Clean vehicle

A clean truck makes a good first impression and signals to inspectors that it’s well cared for. Clear out trash from the cab, wipe down dashboards, and make sure exterior lights and license plates are visible.

Here’s a quick checklist:

- Remove trash and clutter from the cab.

- Wipe down dashboards and interior surfaces.

- Clean windows and mirrors.

- Ensure exterior lights are visible and working.

- Make sure license plates are clean and legible.

4. Double-check vehicle safety kit

DOT rules require certain emergency items to be in your truck. Missing or damaged equipment can lead to violations, even if the rest of the vehicle passes inspection.

Your safety kit should include:

- Three reflective triangles

- A fully charged fire extinguisher

- Spare fuses for electrical systems

- Tire chains (when seasonally required)

- A first aid kit

5. Create an ongoing safety plan

Passing one inspection isn’t enough. You need consistent habits to keep your safety rating strong. Use driver coaching and regular safety meetings to reinforce best practices and address small issues before they turn into big problems.

Key actions:

- Hold regular safety meetings with drivers.

- Review and track fleet management KPIs.

- Address minor maintenance issues before they become serious.

- Document safety practices and follow-up actions.

Stay inspection-ready with Linxup

Good DOT inspection prep means fewer surprises during the inspections and less downtime for your team. It’s all about keeping your trucks safe, drivers protected, and business moving.

Linxup’s GPS fleet tracking solutions give you clear visibility into vehicle health, driver behavior, and route efficiency. With real-time alerts and easy-to-access reports, you can spot issues early and keep crews moving. Book a free demo today and explore how it can help your fleets.

DOT inspection FAQ

What will fail a DOT inspection?

Failures usually come from serious safety issues like faulty brakes, bald tires, broken lights, or missing driver credentials. Cargo that isn’t secured properly or hours-of-service violations can also cause a failed inspection. Inspectors look for anything that puts driver or public safety at risk.

How often is a DOT inspection required?

Most commercial trucks need a full DOT inspection at least once every 12 months. Roadside inspections can happen anytime, especially during safety blitzes or random stops. Some states or jurisdictions might have additional rules, but annual inspections are the general requirement.

Can I do my own DOT inspection on my truck?

You can perform pre-trip checks to catch obvious problems before hitting the road, but official DOT inspections must be done by certified inspectors.

Do you have to be certified to do annual DOT inspections?

Yes, annual DOT inspections must be performed by a qualified and certified inspector. This usually means someone who meets federal or state certification standards, often working for authorized repair facilities or inspection stations. An inspection won’t be valid without certification.

How long does a DOT inspection take?

Most roadside inspections take about 30-60 minutes, depending on the inspection level and truck condition. Annual Level 1 inspections can take longer since they’re more thorough. Being prepared with paperwork and a clean, maintained vehicle helps speed up the process.