Fleet Management Costs: Common Expenses and How To Calculate Them

From fuel to repairs and insurance, fleet management costs can pile up fast. And without a clear way to track them, you might feel overwhelmed and unsure where to begin.

According to a recent Element report, 61% of fleet managers are prioritizing lower total cost of ownership (TCO) to fight inflation, and 51% are zeroing in on reducing maintenance costs. This push shows just how important cost control has become across the industry.

Grow your fleet by exploring the most common fleet expenses and how to calculate them. Knowing your numbers is the first step toward reducing fleet costs.

What are fleet management costs?

Fleet management costs are the expenses that come with owning and running a group of vehicles. It’s similar to running a household. There are regular bills you can predict, such as your monthly mortgage or rent, and variable ones that change depending on use, like the electricity bill. Fleets work the same way, with fixed and variable costs.

Knowing these costs helps you build a stronger fleet. When you understand where money is going, you can plan better, cut waste, and make smarter choices that keep vehicles running smoothly and profitably.

Top fleet costs and how to tackle them

Running a fleet means handling a mix of fixed and variable expenses. Below are the key cost areas you’ll face, along with practical ways to keep them under control.

Fixed costs

Fixed costs stay the same month to month. They’re easier to predict but still need planning to avoid overspending.

Examples include:

- Insurance premiums

- Licenses and permits

- Vehicle financing or leases

- Depreciation

To reduce fixed costs, shop around for better insurance rates, negotiate loan terms, and make sure you’re not paying for unused vehicles. Spreading out costs with proper budgeting keeps your fleet stable in the long run.

Variable costs

Variable costs shift depending on how much your fleet is on the road. They make up a large part of overall spending.

Examples of variable costs include:

- Fleet fuel cost

- Repairs and maintenance

- Tires and parts

- Overtime and driver wages

To reduce variable costs, monitor expenses closely and address issues early. Route planning, better driving habits, preventative maintenance, and reducing idle time can cut fuel use and lower wear on vehicles. This also helps reduce fuel shrinkage, which can quietly eat into profits. Using automation to track trends and monitor costs can also help reduce variable spending. You can easily spot problems to address them early and avoid manual reporting which can be prone to error.

Technology costs

From software to hardware, technology plays a big role in modern fleet operations. These tools improve efficiency but can add up eventually.

Examples include:

- Fleet tracking systems

- Telematics devices

- Dash cams and sensors

- Data storage for customer data

To reduce technology costs, start by auditing your tools regularly. Choose solutions that combine features instead of paying for multiple overlapping systems. Scale plans to fit your fleet size so you don’t overpay for unused features.

Driver and safety costs

People are the backbone of any fleet, but training and safety measures come with a price. Still, these are investments that save money over time.

Examples of these costs include:

- Training programs

- Safety equipment

- Compliance fines or penalties

- Accident-related expenses

To reduce driver and safety costs, invest in driver coaching and clear safety policies. A well-trained driver reduces accidents, saves fuel, and extends vehicle life. Prevention is always cheaper than paying for avoidable mistakes.

How to calculate the total cost of ownership

Looking at the total cost of ownership helps you see beyond the purchase price and understand the real fleet management cost per vehicle. It includes fixed expenses like insurance and financing, variable costs like fuel and repairs, and even technology and driver-related costs.

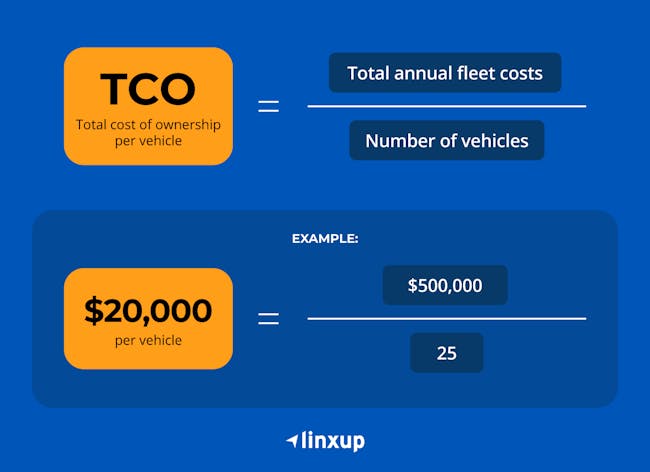

To calculate TCO:

- Add up all annual fixed, variable, technology, and driver costs for your fleet.

- Divide the sum by the number of vehicles.

Formula: TCO per vehicle = Total annual fleet costs ÷ Number of vehicles Example: If your fleet costs $500,000 to run in a year and you have 25 vehicles, your TCO will be: $500,000 ÷ 25 = $20,000 per vehicle per year |

Tracking the TCO regularly helps you spot trends and make smarter decisions. And having a solid fleet maintenance plan makes TCO more predictable, minimizing surprises and keeping vehicles on the road longer.

How to calculate cost per mile (CPM)

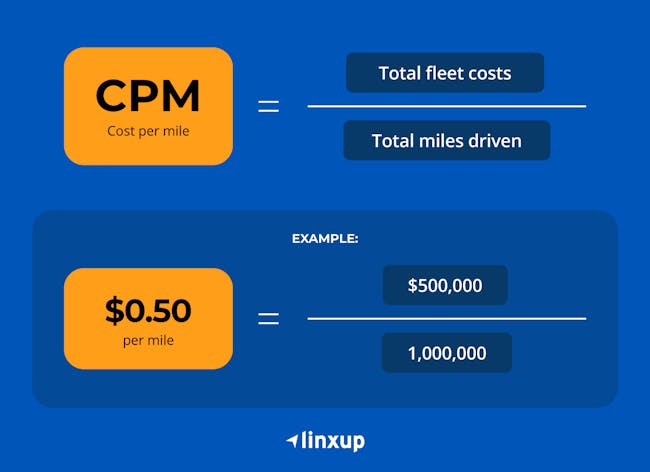

Cost per mile shows how much it costs to run your fleet for every mile driven. It’s a simple but powerful way to measure efficiency and compare performance across vehicles. CPM is often used in fleet management cost analysis because it highlights where you're losing money and where you can make improvements.

To calculate CPM:

- Take your total fleet costs over a set period (monthly or yearly).

- Divide the sum by the total miles driven in that same period.

Formula: CPM = Total fleet costs ÷ Total miles driven Example: If your fleet costs $500,000 to run in a year and drives 1 million miles, then your CPM will be: $500,000 ÷ 1 million = $0.50 per mile |

Monitoring CPM helps you see the real cost of every trip. Pairing this with a strong fleet safety program can bring costs down further by reducing accidents, cutting downtime, and extending vehicle life.

How to use TCO and CPM to manage your fleets better

Knowing your TCO and CPM gives you a deeper view of your fleet’s performance. These numbers help you set priorities, cut waste, and build a smarter strategy.

Here are some ways to put them to work:

- Track progress with fleet management KPIs: Compare TCO and CPM against your KPIs to see if costs are trending up or down.

- Spot underperforming vehicles: Use TCO to identify which vehicles are too expensive to keep on the road and may need to be replaced.

- Guide budgeting decisions: CPM helps forecast how much future routes or new contracts will actually cost.

- Improve efficiency with telematics systems: Combine cost data with real-time tracking and telematics data to spot fuel waste, harsh driving, or poorly planned routes.

- Strengthen maintenance planning: Use TCO trends to refine service schedules and prevent breakdowns before they happen.

- Support driver training: High CPM tied to poor driving habits can guide where more coaching is needed.

Think of it as a cycle:

- Measure or calculate TCO and CPM.

- Compare them against your benchmarks and goals.

- Act on the insights by adjusting vehicles, routes, or training.

- Repeat this cycle to take your fleet management strategy from reactive to proactive.

5 ways fleet management software reduces operational costs

The best fleet management systems can help you reduce waste, improve efficiency, and extend vehicle life. Here are some ways you can use fleet tracking software like Linxup to lower operational costs.

1. Route optimization

Optimized routing cuts down on wasted miles and lowers fuel use. Linxup’s software shows drivers the most efficient routes in real time, saving both time and money on every trip. It also helps reduce wear and tear on vehicles — fewer miles means less strain on engines and tires.

2. Proactive maintenance alerts

Staying ahead of maintenance keeps vehicles efficient, safer, and compliant. Linxup sends automated alerts for service needs, which reduces the risk of breakdowns, costly fines, and accidents caused by poorly maintained vehicles.

3. Resource allocation

Fleet tracking helps you see exactly how your vehicles are being used. With this insight, you can make informed decisions about the right number and type of vehicles needed, avoiding unnecessary purchases. Linxup data can guide whether to buy, lease, or rent, depending on your needs.

4. Administrative efficiency

From mileage reports to compliance records, software simplifies the paperwork that eats up valuable hours. Linxup automates reporting and task tracking, freeing managers to focus on running a stronger fleet instead of drowning in admin work.

5. Driver coaching

Driver behavior directly affects costs. Linxup highlights habits like harsh braking, speeding, and idling so you can coach drivers toward safer, more efficient practices. This reduces wear and tear, lowers fuel costs, and promotes safer driving across the fleet.

It doesn’t even cost a fortune to get these benefits. Fleet management software cost depends on fleet size and features, but you can expect to pay $15-$50 per vehicle per month, on average. And that cost quickly pays for itself through smarter operations.

Keep your fleet in check with Linxup

Running a fleet comes with plenty of fleet management challenges, and managing costs is one of them. Without clear visibility into your TCO and CPM, it’s tough to track your money and keep expenses under control.

Linxup’s fleet tracking solution helps you manage fleet costs with features like real-time tracking, route optimization, maintenance alerts, and driver coaching. It’s easy to install, and you can access it through our mobile app.

Request a free demo today to know more about our tracking solution and get a handle on your fleet management costs.